Due to its stability at temperatures above 350°C nitrate-nitrite mixtures of Molten Salt have been widely used in heat transfer technology in the production organic & fine chemicals, Anhydrides, caustic soda, melamine, Glass manufacturing, metal refining and steel industry.

AURO PUMPS manufactures Molten Salt Pumps as well as entire Molten Salt systems or Molten Salt Loops for various industry sectors. These Molten Salt Loops are custom designed to suit the specific needs of every customer.

- Specially designed autonomous system with pumped Molten Salt for research & development of new processes and chemical experiments

- System’s operating temperature ranges from 200°C to 700°C making it an invaluable platform for developing new processes or carrying out both endothermic and exothermic chemical reactions in the same setup

- AURO’s Molten Salt Loops include a Salt storage & melting module, Molten Salt Pump, reactor module (Heat exchangero sample chamber), cooling module (if required), valves, temperature sensors, pressure sensors (for blanketgas),etc.

- Every Molten Salt Loop comes with an automated control panel consisting of digital data display and data acquisition features.

- Gravity drain design of entire system to prevent the molten salt from setting in the pipeline and other equipment when the pump is not in operation.

- Molten Salt Loop with single point electric heating or dual point steam plus coal/gas/electric heating option savailable.

- Available in a lab scale portable loop, modular design pilot scale loop and full scale production loop.

- Molten Salt Loops available for Nitrate-Nitrite salts, Fluoride and Chloride Salts.

We at AURO PUMPS aim to push the envelope and are always willing to participate in the development of new and customized pumping solutions. Customized Pumping and Loop solutions can be provided on request.

Molten salts also display a high heat retention capacity as well as higher stability at elevated temperatures as compared to HTF oil which has led to the extensive use of molten salt in the solar energy sector as both a heat transfer and thermal storage fluid.

Molten Salt Solar Power plants are of 2 types, Heliostat Central Tower with Molten Salt & heat storage and Parabolic Trough with Molten Salt heat storage.

- Specially designed autonomous system with pumped molten salt for research & development of new processes

- System’s operating temperature ranges from 200°C to 550°C making it an invaluable platform for testing of pilot scale concentrated solar power plants

- AURO’s molten salt loops for solar application include a Salt storage & melting module, Hot & Cold molten salt pumps, control valves, requisite temperature sensors, pressure sensors (for blanket gas), etc. (AURO only manufactures the molten salt system, AURO does not supply the solar equipment or power generation systems)

- Every Molten Salt Loop comes with an automated control panel consisting of digital data display and data acquisition features

- Gravity drain design of entire system to prevent the molten salt from setting in the pipeline and other equipment when the pump is not in operation

- Available in a lab scale portable loop and modular design pilot scale loop

- Loops available for nitrate-nitrite salts, fluoride and chloride salts

We at AURO PUMPS aim to push the envelope and are always willing to participate in the development of new and customized pumping solutions. Customized Pumping and Loop solutions can be provided on request.

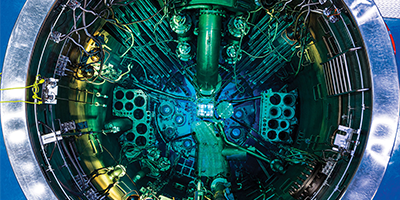

Fluoride based molten salts have also been used as the primary coolant in Molten Salt Reactors (MSRs) which are a class of Nuclear Fission Rectors. The salts concerned as primary coolant, mostly lithium-beryllium fluoride and lithium fluoride, remain liquid without pressurization from about 500°C up to about 1100°C, in marked contrast to Pressurized Water Reactors (PWRs) which operate at about 315°C under 150 atmospheres pressure thus making it one of the most sought after technologies across the world with many countries like India, USA, Germany, France, China, etc. racing to develop MSRs.

- Specially designed autonomous system with pumped molten salt for R&D experiments, materials & components testing in salts, etc.

- System’s operating temperature ranges from 200°C to 700°C making it an invaluable to help carry out R&D and experiments

- AURO’s Molten Salt Loops consist of a salt storage & melting module, molten salt pump, reactor module (Heat exchanger or sample chamber), cooling module (if required), control valves, temperature sensors, pressure sensors (for blanket gas), etc.

- Every Molten Salt Loop comes with an automated control panel consisting of digital data display and data acquisition features

- Gravity drain design of entire system to prevent the molten Salt from setting in the pipeline and other equipment when the pump is not in operation

- Lab scale portable loop available

- Loops available for nitrate-nitrite salts, fluoride and chloride Salts

We at AURO PUMPS aim to push the envelope and are always willing to participate in the development of new and customized pumping solutions. Customized Pumping and Loop solutions can be provided on request.